I know that many of you here have some sort of engineering education and/or experience in mechanical enginnering job, or are enthusiasts just like me who love exploring all aspects of their hobby. I admit that I haven't done enough research myself neither in Slovak literature nor English one, but I haven't been able to find what I want to know in English books which I downloaded.

I'm desperately interested in what makes mechanical engineer to make final decision when choosing bearings or bushings? What's the last grain of sand that leads to resulting decision? Is there any methodology to help in this?

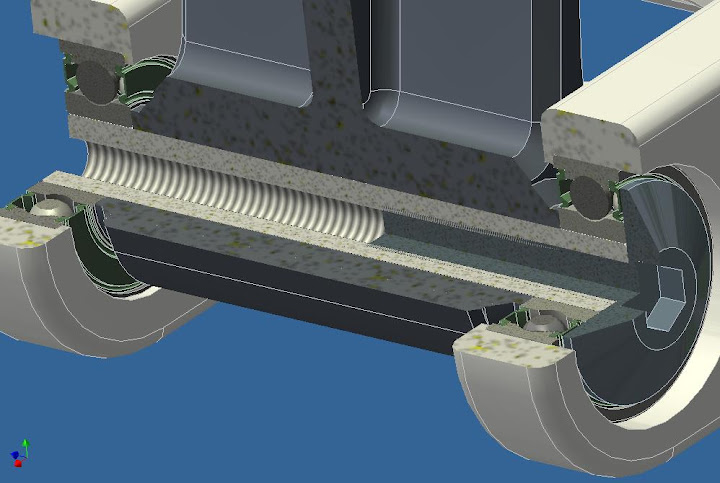

Obviously, you can pick bushings that can take damn high loads, work under water or in the dust and need no lubrication. I know that there's no ideal bushing material and their qualities highly depend on axle material and finish used. We know that Keith Scott quit bushings in Legend Mk2 as they were "eating" 7075 pivot axles on Mk1. Now, the new Banshee Prime runs on sealed bearings.

What would you base your decision on if you'd find yourself stuck, deadlock, in design process?

Thanks for any advice.

I'm desperately interested in what makes mechanical engineer to make final decision when choosing bearings or bushings? What's the last grain of sand that leads to resulting decision? Is there any methodology to help in this?

Obviously, you can pick bushings that can take damn high loads, work under water or in the dust and need no lubrication. I know that there's no ideal bushing material and their qualities highly depend on axle material and finish used. We know that Keith Scott quit bushings in Legend Mk2 as they were "eating" 7075 pivot axles on Mk1. Now, the new Banshee Prime runs on sealed bearings.

What would you base your decision on if you'd find yourself stuck, deadlock, in design process?

Thanks for any advice.

. Axle OD is 12mm if I remember correctly.

. Axle OD is 12mm if I remember correctly.