If your going to mock me, then do it straight up, no sarcasm please.

The winter months make me( and i think alot of people) loopy and itching to ride.

I have always wanted to design and build my own downhill frame.

My first frame will most likely be Mild or Chromoly Steel ( dont really care if it will weigh 55 pounds + ) and most likely a single pivot. As my knowledge and frame building skills increase, I will graduate to multi linked, Aluminum frames

I do have AUTOCAD designs( which i took 2 years of college courses of) of a really "interesting and out there" suspension design.

I have the skills and knowledge of G.T.A.W (Gas Tungsten Arc Welding). I graduated with an Associates in Welding Technology( We covered M.I.G, T.I.G, Stick, Oxy-Acet welding). I have learned how to weld those process's just mentioned on Mild Steel and Aluminum.

At my new job (which I was blessed to receive a full time, 40 hour work week) I am a full time welder/ machinist. I was STOKED to get my hands onto some bridgeport milling machines and lathes. I now know how to use a Daewoo A20 60" Lathe like the back of my hand! I also learned how to read inside/ outside micrometers and all the "thousandths" measuring devices.

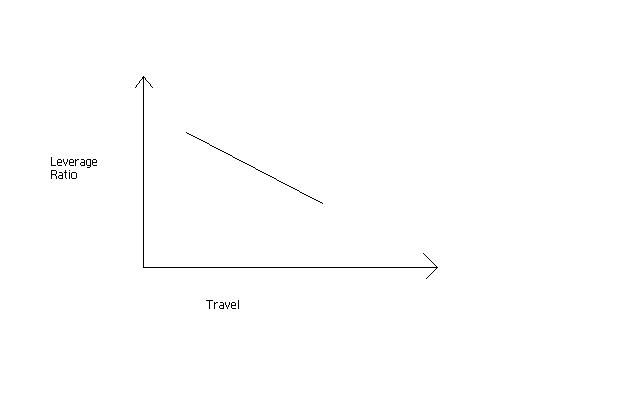

OKAY, now that im done giving ridemonkey my life story, I am interested in seeing how frame builders/ frame designers figure out how to design swingarms and front triangles in accordance to shock placement and leverage ratios. now i am just talking about single pivots here, I cant even imagine how they design/ cut/ cnc mill links for multi link bikes, like M6, Liaperre exc exc.

Now i am aware i did not major in Engineering and Physics, so please dont butcher me haha.

So...how do you smarties do it?!

I would show you my "wild" 3-d frame design that i designed over the past 2 years, but my computer has a nasty virus, and I havnt had the time to invest to remove the virus.

take 'er easy

-jordan

The winter months make me( and i think alot of people) loopy and itching to ride.

I have always wanted to design and build my own downhill frame.

My first frame will most likely be Mild or Chromoly Steel ( dont really care if it will weigh 55 pounds + ) and most likely a single pivot. As my knowledge and frame building skills increase, I will graduate to multi linked, Aluminum frames

I do have AUTOCAD designs( which i took 2 years of college courses of) of a really "interesting and out there" suspension design.

I have the skills and knowledge of G.T.A.W (Gas Tungsten Arc Welding). I graduated with an Associates in Welding Technology( We covered M.I.G, T.I.G, Stick, Oxy-Acet welding). I have learned how to weld those process's just mentioned on Mild Steel and Aluminum.

At my new job (which I was blessed to receive a full time, 40 hour work week) I am a full time welder/ machinist. I was STOKED to get my hands onto some bridgeport milling machines and lathes. I now know how to use a Daewoo A20 60" Lathe like the back of my hand! I also learned how to read inside/ outside micrometers and all the "thousandths" measuring devices.

OKAY, now that im done giving ridemonkey my life story, I am interested in seeing how frame builders/ frame designers figure out how to design swingarms and front triangles in accordance to shock placement and leverage ratios. now i am just talking about single pivots here, I cant even imagine how they design/ cut/ cnc mill links for multi link bikes, like M6, Liaperre exc exc.

Now i am aware i did not major in Engineering and Physics, so please dont butcher me haha.

So...how do you smarties do it?!

I would show you my "wild" 3-d frame design that i designed over the past 2 years, but my computer has a nasty virus, and I havnt had the time to invest to remove the virus.

take 'er easy

-jordan

.

.