Well, long story short, i got a job at a metal shop and have the opportunity to actually make a frame of my choice. Problem, i don't know **** about designing let alone don't have enough money to learn the programs i want to use..

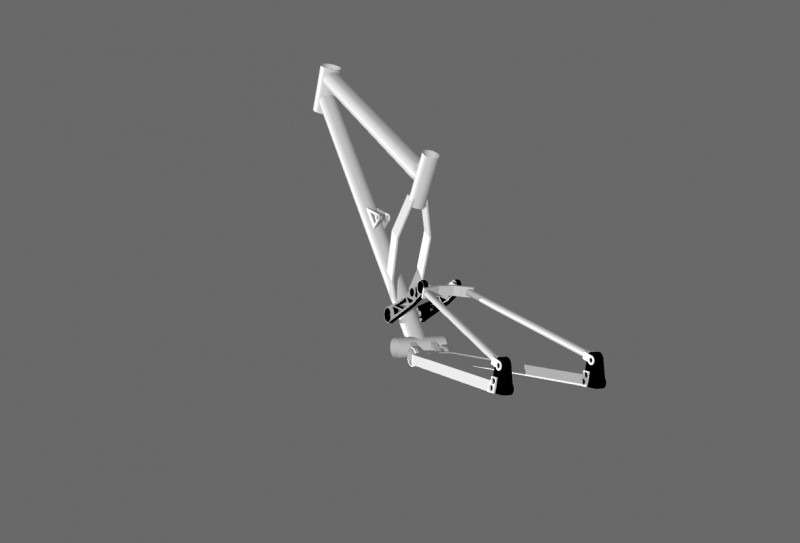

So, does anyone have any frame designs that i could use? I would ideally want a high piviot 5'' frame. Steel it is going to be no mater what. 66-67 degree headtube? 22 tt? linear rate?

Not sure really, but if people have designs that could be made, post em up!

Thanks!

So, does anyone have any frame designs that i could use? I would ideally want a high piviot 5'' frame. Steel it is going to be no mater what. 66-67 degree headtube? 22 tt? linear rate?

Not sure really, but if people have designs that could be made, post em up!

Thanks!

I'm the least of your worries out there lol. Your prices are a little exagerated as well.

I'm the least of your worries out there lol. Your prices are a little exagerated as well.