Ok, I have been toying with the idea of having some angled 1.5 to integrated standard reducers made to reduce or increase 1 degree of headangle. I am pretty confident that I could get some made that will do what I want and be applicable to a smll range of headtube lengths (+- 0.5") due to the ACB and crown race shape. THey would consist of two identical parts (top and bottom), rather than the single unit that another Monkey made.

I have a few questions that I was hoping some one might be able to help with

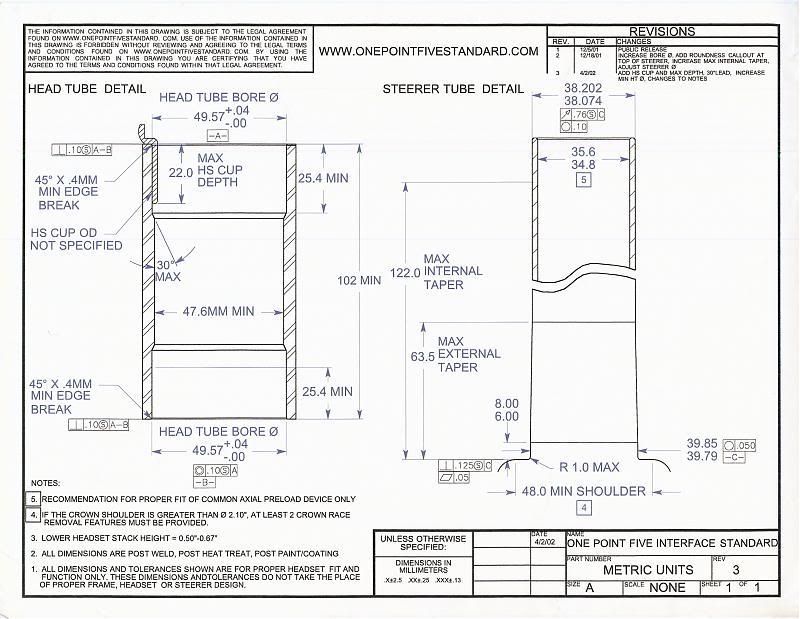

1) I canont find the 1.5 standard tech drawings any more. Does anyone know any specific measurements and tollerances for the bearing seat and external diameter. ( I can mic a part that I have, but I would need to remove from the frame and then remove the bearing). BYO, I know you made some non-angled versions at one time.

2) I have roughly drawn the part in Autodesk as I have it on my laptop...but I could most likely get acces to SW. Will the modeling software matter to the machinist? Do I need to get this into some CNC code, or is something that the machinist will/can do from the SW or autodesk files (sorry, EE not ME)?

3) Any rough idea how many of these I would need to get made to get a reasonable price? Zenkgarage..BYO??? 10? 100?

Any other info/data anyone wants to share? DW, I know you had some of these made....

Thanks

I have a few questions that I was hoping some one might be able to help with

1) I canont find the 1.5 standard tech drawings any more. Does anyone know any specific measurements and tollerances for the bearing seat and external diameter. ( I can mic a part that I have, but I would need to remove from the frame and then remove the bearing). BYO, I know you made some non-angled versions at one time.

2) I have roughly drawn the part in Autodesk as I have it on my laptop...but I could most likely get acces to SW. Will the modeling software matter to the machinist? Do I need to get this into some CNC code, or is something that the machinist will/can do from the SW or autodesk files (sorry, EE not ME)?

3) Any rough idea how many of these I would need to get made to get a reasonable price? Zenkgarage..BYO??? 10? 100?

Any other info/data anyone wants to share? DW, I know you had some of these made....

Thanks

)

)