Tomac and Honda (Gearbox bike)

- Thread starter Total Heckler

- Start date

I like BCD's implementation better. Plus, Alex was way ahead of the game.

I get your other points but how could there be more proprietry parts than in a Rohloff?i'm a litte sceptical of derailleurs in a can for a few reasons - there will still need to be a bunch of proprietary bits in there, there's still adjustment & fine tuning requirements, and said tuning & the replacement of wearing bits (though there's no dirt contamination, you're still dragging a chain across cogs) will require cracking the case open, so there's an added labor component

The DiaB concept has the advantage of being heaps lighter than a Rohloff too.

Does Rohloff have a trigger shifter option at all? Or does the push-pull actuation require a twist shifter?

DiaB = readily available parts should you need them, plus they are a lot more user serviceable. Pull apart a Rohloff or Shimano hub and try and put it back together and get it working! DIAB FTW! It ticks all the boxes for DH application I reckon.I get your other points but how could there be more proprietry parts than in a Rohloff?

The DiaB concept has the advantage of being heaps lighter than a Rohloff too.

Does Rohloff have a trigger shifter option at all? Or does the push-pull actuation require a twist shifter?

I get your other points but how could there be more proprietry parts than in a Rohloff?

protip:Pull apart a Rohloff or Shimano hub and try and put it back together and get it working!

no reason to take it apart if it never stops working in the first place.

The rohloff hub has a lot of downfalls...reliability and maintenance are not one of them. Weight, drag, drivetrain lash, etc....but I have never heard somebody say their rohloff hub needs to be disassembled and put back together. DH riders are complete fairies but I can't imagine any of them putting more hurt than a trail/xc rider.

His username is ÆX now and I believe he owns a bike shop in Amarillo called BikeLife.speaking of which, what happened to bcd? Haven't seen him around these parts in a long time.

With a derailleur in a box you can run a basic cassette, cogs, chain, and derailleur. Proprietary parts would be only those to tie it all together.I get your other points but how could there be more proprietry parts than in a Rohloff?

The DiaB concept has the advantage of being heaps lighter than a Rohloff too.

Other advantages also include less (un?)sprung weight and shifting it under you creating a more centered and low center of gravity.

Whatever happen to the electronic gearbox bike from Spooky? Haven't seen anything on that in a while.

There is a guy here in Spain that is tunning a Rolhoff, and he is doing an amazing job. Check it out here... LINKprotip:

no reason to take it apart if it never stops working in the first place.

The rohloff hub has a lot of downfalls...reliability and maintenance are not one of them. Weight, drag, drivetrain lash, etc....but I have never heard somebody say their rohloff hub needs to be disassembled and put back together. DH riders are complete fairies but I can't imagine any of them putting more hurt than a trail/xc rider.

He has machined a few internal parts and tuned all the accesories, saving more than a pound.

could you though? the honda is certainly fully custom inside. you could use a stock cassette, but you'd still need a hub of sorts to carry it. i don't think you could use a fixed mount rd as the chain deflection is too great over a short distance. you'd have to do some sort of mount on a sliding shaft (so it tracks laterally as you shift). and enclosing the assembly & configuring input & output shafts to the thing is going to require more bits & a whack of manufacturing costs / engineering. i bet you could implement a stock gearhub like an alfine for cheaper (developmentally as well as from a production standpoint).With a derailleur in a box you can run a basic cassette, cogs, chain, and derailleur.

i won't say the rohloff is ideal for the reasons mentioned (weight, expense, too many gears for the application, no trigger option, etc), but i think the configuration is the best gearbox format (in terms of production viability) to date. i think the zerode w/ the alfine could be a winner - if it ever makes it to production.

I saw someone at a UK DH race last weekend with a home-made frame complete with derailleur-in-a-box (but without the box) frame-mounted gears.

I didn't pay much attention to it really, wish I'd looked more at how the gears worked. Anyone on here know whose that was?

I didn't pay much attention to it really, wish I'd looked more at how the gears worked. Anyone on here know whose that was?

for sure. i'm just a bit of a futurist though and think at the upper end of the spectrum (ie, bikes nearing moto prices) we should be expecting similar levels of durability & low maintenance. ie, apart from replacing wearing bits like tires & oiling your chain, being able to ride your bike for a season w/o maintenance. the exposed derailleur transmission is certainly the weakest link in the system.Realistically though, deraileur systems don't require as much maintenance as people make out. Given how exposed they are, they do put up with a lot of crap.

we'll get that when DH bikes start selling in the same quantities as motos. maybe. at the very least just lower prices.for sure. i'm just a bit of a futurist though and think at the upper end of the spectrum (ie, bikes nearing moto prices) we should be expecting similar levels of durability & low maintenance. ie, apart from replacing wearing bits like tires & oiling your chain, being able to ride your bike for a season w/o maintenance. the exposed derailleur transmission is certainly the weakest link in the system.

You are right, a Db in a box is not such a straight forward solution, a lot of work is needed to fit the components in. you should look at the new alfine, 11 gears and at 1.6 kg. (a little bit liter than the speedhub - 1.736kg) it is not that heavy. I am currently running an alfine 8 wheel mounted at the wheel and it has been spotless for over two years and best of all, maintenance free. it shifts under heavy pedaling, cruising or when standing. Alfines only cost a fraction of a speedhub, they come with trigger shifter and they can surely take the pounding. the sprung weight hasn't been a big deal (mind you, I am not a pro, or not even close) and they are far more reliable than a DB. I am as exited as everyone else to see that zerode ready. the alfine in a box option is a serious contender to be a true and cheap alternative to a g-boxx or any other gearbox bike, even if it is a db on a box. oh an the gear range is pretty decent too.could you though? the honda is certainly fully custom inside. you could use a stock cassette, but you'd still need a hub of sorts to carry it. i don't think you could use a fixed mount rd as the chain deflection is too great over a short distance. you'd have to do some sort of mount on a sliding shaft (so it tracks laterally as you shift). and enclosing the assembly & configuring input & output shafts to the thing is going to require more bits & a whack of manufacturing costs / engineering. i bet you could implement a stock gearhub like an alfine for cheaper (developmentally as well as from a production standpoint).

i won't say the rohloff is ideal for the reasons mentioned (weight, expense, too many gears for the application, no trigger option, etc), but i think the configuration is the best gearbox format (in terms of production viability) to date. i think the zerode w/ the alfine could be a winner - if it ever makes it to production.

Last edited:

Black home built thing with a huge swingarm, English guy riding it?I saw someone at a UK DH race last weekend with a home-made frame complete with derailleur-in-a-box (but without the box) frame-mounted gears.

I didn't pay much attention to it really, wish I'd looked more at how the gears worked. Anyone on here know whose that was?

If ya, seen that at an Innerz uplift about a month back, gutted I didn't get pics of it but I was having a **** day and was in a huffy mood!

Looked pretty impressive for a first attempt, think it had 5 gears.

that was a neat system. looked pretty simple, and used lots of standard bits. i seem to recall him saying he had performance issues with it however.I like BCD's implementation better. Plus, Alex was way ahead of the game.

anybody have bigger pix?

littermag did a slideshow a few years agoanybody have bigger pix?

litter feature was on bcd 29er dh bike, not gearbox unfortunately.littermag did a slideshow a few years ago

gotcha. i thought it had a gearbox too.litter feature was on bcd 29er dh bike, not gearbox unfortunately.

thnx

must know moar!

Last edited:

haha, yeah those double barrels were pimp (back in the custom cnc everything days...)oh hells yes caramba cranks...

i love bcd's concepts though. wish he were still building. he used to have drawings of a gearhub based gearbox design on his site as well.

this concentric design w/ nexus was one of the first gearbox bikes like, ever (came out in '97 - same time as the brodie & gt bikes; not sure who can take the official 1st claim):

What do You want to know?must know moar!

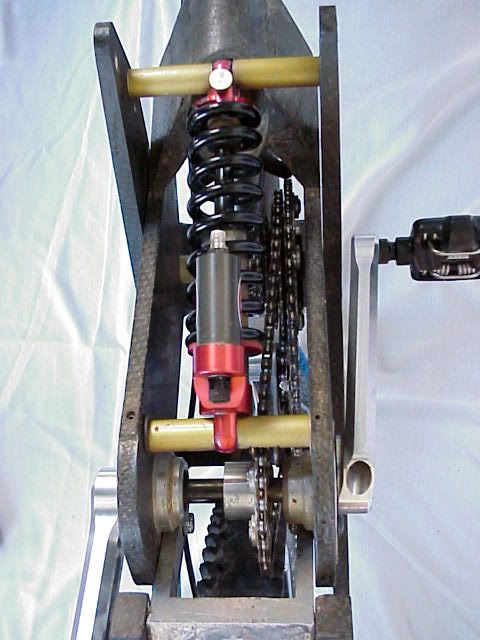

As You can see, there is a sprocket fixet to the bb spindle. Than You have regular der. and freewheel with 6 cogs and 7th cog as an output sprocket. Simple as hell : )

so the cassette is constantly in motion which allows you to shift while coasting? is there no freehub on the rear wheel?As You can see, there is a sprocket fixet to the bb spindle. Than You have regular der. and freewheel with 6 cogs and 7th cog as an output sprocket. Simple as hell : )

edit: actually, that wouldnt work because its attached to the bb spindle right?

Exactly, cassette engages only when You are pedalling. It can't be in motion constantly because You would have a fixie. You would have to put a freewheel on bb spindle sprocket like on DC Special Frame to shift while coasting.so the cassette is constantly in motion which allows you to shift while coasting? is there no freehub on the rear wheel?

edit: actually, that wouldnt work because its attached to the bb spindle right?

From the looks of it, since the brake is on the 'driveside' he would have probably flipped the hub. The freewheel on the hub would then be reversed . The chain then feeds to a cog driving a freewheel within the frame. This basically relocates the entire freewheel motion and cassette within the frame. Since the hub is flipped, the chain from the rear hub would be continuously moving, but the cassette does not until you start to pedal. Using all basic parts now found on a bike except for those to tie it all together (ie: bb spindle, sprocket on bb spindle, spindle for the cassette and freewheel mech, mount for rear derailleur)so the cassette is constantly in motion which allows you to shift while coasting? is there no freehub on the rear wheel?

edit: actually, that wouldnt work because its attached to the bb spindle right?

However the humble old derailleur still the best of the worst for efficiency and durability when compared what the market currently provides

All of the shimano hubs are certainly not durable for proper DH racing.. While the CTV is still not as efficient as a chain drive...

All of the shimano hubs are certainly not durable for proper DH racing.. While the CTV is still not as efficient as a chain drive...

you sure bout that? people are using them with success on MTBs...I think the big problem is that you cannot run a super low granny gear for fear of destroying the hub's clutch. Nobody has found a way to mount one centrally, save for the failhar and the zero(bikes ever produced)de. They don't readily mount up to a rear triangle on a DH bike too.All of the shimano hubs are certainly not durable for proper DH racing.. While the CTV is still not as efficient as a chain drive...

There is no doubt CVT are being used without some success.. Fear of using granny probably equates to someone like Rennie at full tilt. - have not done the math..you sure bout that? people are using them with success on MTBs...I think the big problem is that you cannot run a super low granny gear for fear of destroying the hub's clutch. Nobody has found a way to mount one centrally, save for the failhar and the zero(bikes ever produced)de. They don't readily mount up to a rear triangle on a DH bike too.

Mounting a CVT shouldnt pose a problem if the bike and hardware is designed specific for the purpose..

Straight from the nuvinci

"What is the ratio range and efficiency of the NuVinci CVP hub?

From bench and road testing by potential consumers and industry experts, the NuVinci CVP compares favorably with the internally geared hubs on the market today and has the same or better ratio range.."

I guess it comes down to compromise and probability... ripping off a derailleur vs % of drive train drag ~ 15% (dont quote me as there are many variants)

from the rohloff site: "the working efficiency of the Rohloff SPEEDHUB 500/14 is brought up to 96% (for gears #1 to #7) and 98% (for gears #8 to #14)"

can't confirm the accuracy (seems optimistic), of course, but i don't find drag to be discernible / detrimental.

can't confirm the accuracy (seems optimistic), of course, but i don't find drag to be discernible / detrimental.

I think we misunderstand each other. I was talking about internally geared hubs like the alfine and brohloff, not the nuvinci. The IG hubs are tested and proven, the cvt is way too heavy and awkward for a DH bike, let alone an XC sled.There is no doubt CVT are being used without some success.. Fear of using granny probably equates to someone like Rennie at full tilt. - have not done the math..

Mounting a CVT shouldnt pose a problem if the bike and hardware is designed specific for the purpose..

Straight from the nuvinci

"What is the ratio range and efficiency of the NuVinci CVP hub?

From bench and road testing by potential consumers and industry experts, the NuVinci CVP compares favorably with the internally geared hubs on the market today and has the same or better ratio range.."

I guess it comes down to compromise and probability... ripping off a derailleur vs % of drive train drag ~ 15% (dont quote me as there are many variants)

No worries.. gotcha.I think we misunderstand each other. I was talking about internally geared hubs like the alfine and brohloff, not the nuvinci. The IG hubs are tested and proven, the cvt is way too heavy and awkward for a DH bike, let alone an XC sled.

On the IG...

I was really keen to build something around the 11sp alfine due to some speculation of it's capabilities - but alas its not even rated for spirited riding - eg road bike + hills... not to mention off road..

I understand Shimano is somewhat conservative in these matters... hence making a commercial gbox DH based on these products is not going to happen on anything than a very small scale...

Im sure it is all in the works from a number of fronts to kill the humble derailleur - at least we can hope

"telescoping dual UJ alu. shaft drive with gearbox...would open up alot of suspension possibilities."

The old crazy man yelled before dispairing into the wood once again!

The old crazy man yelled before dispairing into the wood once again!

Did anyone mention Pinion P-1 gearbox, yet?

http://forums.mtbr.com/showpost.php?p=7275804&postcount=1

Ok, Wilhelm did

http://www.ridemonkey.com/forums/showpost.php?p=3512558&postcount=417

http://forums.mtbr.com/showpost.php?p=7275804&postcount=1

Ok, Wilhelm did

http://www.ridemonkey.com/forums/showpost.php?p=3512558&postcount=417

Last edited:

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.