It is 1011110101101 alloy.This. Someone should send them an email, what the fuck "8-bit alloy" really is.

Best 35mm DM stem?

- Thread starter Udi

- Start date

-

- Tags

- clamp it now

yeah. in 25.4 they have.Has CRC finally run out of Funn Full On bars?

If you ever clean out your hole. I'd definitely buy them. (I run one of CRCs last batch of 710 full-on's on one of my hardtails).

I'll see what I can squat.yeah. in 25.4 they have.

If you ever clean out your hole. I'd definitely buy them. (I run one of CRCs last batch of 710 full-on's on one of my hardtails).

Deity uses 7075 T3 aluminium but no 35mm stem - yet.

Their stuff is light.

Didn't Brendog say something of a new bar and stem in the last team video?

Their stuff is light.

Didn't Brendog say something of a new bar and stem in the last team video?

Wife's Easton for reference, as you can see the "clamp" itself is similar in width to the ANVL, but WHERE it clamps to the bars is wider than the ANVL. Running a small stem spacer under her stem so we can keep the bars out of the compression adjust on the 40. She is running in the 40 or 45 mm reach (can't recall but its the shorter choice)Great, thanks for the update. Any pics of the combo? Do the front bolts take a 4mm or 5mm key?

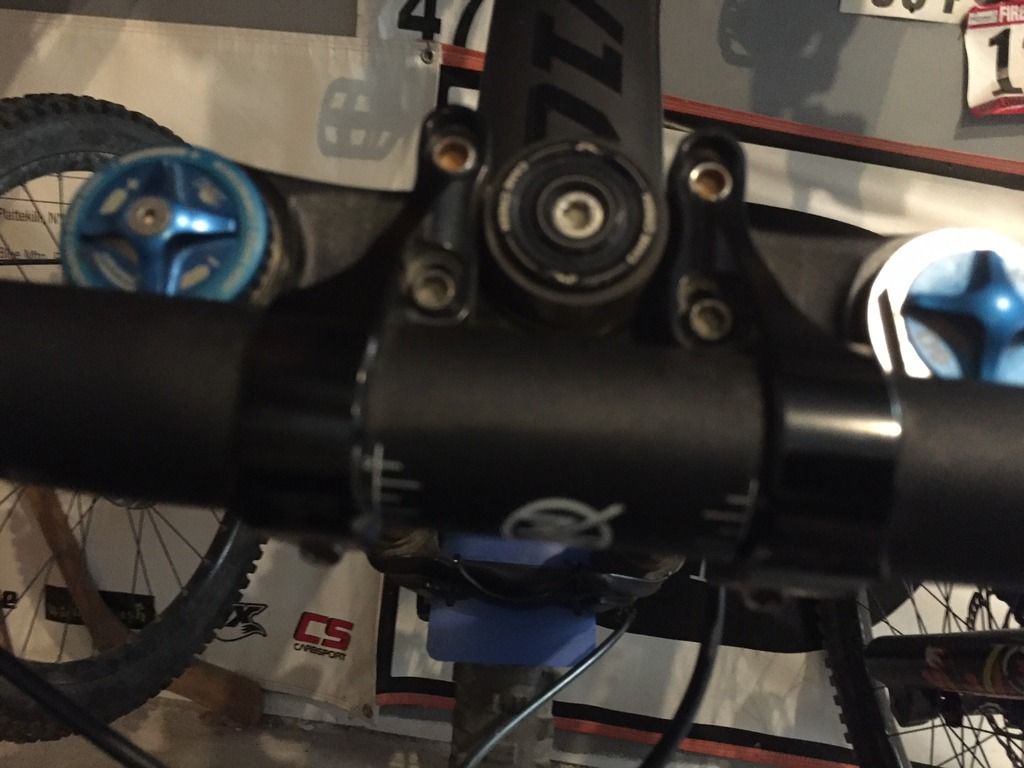

Pics of my ANVL stem and bar combo.

All of the bolts on the ANVL Stem are 5mm Allens, both the clamps and the bolts that go into the crown.

Moose: "Eight bit alloy: 1011110101101"It is 1011110101101 alloy.

Squirrel: "That's thirteen bits"

Moose: "I'm a heavy tipper"

@Gary I'm running a fresh set of 750 funn full on bars on my hardtail- I love these bars- wish they didn't stop making them. Machined some spacers to fit a stem that's stiffer than those old Thomsons... Oh, hey, wanna buy a 50 OR a 70mm 25.4 Thomson stem?

Edit: please excuse the cable rats nest. Stuck with a lockout lever if I want any compression adjust on this Reba fork :/

Edit: sorry for the derail Udi!

Edit: please excuse the cable rats nest. Stuck with a lockout lever if I want any compression adjust on this Reba fork :/

Edit: sorry for the derail Udi!

Other than looks I was never a huge fan of

Thanks for keeping me in mind tho.

@Udi's gotta be used to this shit by now. There's a wee messaging system up in the top right so we don't bother him. But where's the fun in that?

Oh... and if you really want one less noodle flailing around your bars. use a short section of derailleur cable to pinch the comp adjuster in the position you want it on the Reba. You don't actually adjust compression damping or bother with lockout on a Hardtail. Do you? :/

. sorry dude. Plus I run a 40mm stem on my HT. DM on DH bike.those old Thomsons

Thanks for keeping me in mind tho.

@Udi's gotta be used to this shit by now. There's a wee messaging system up in the top right so we don't bother him. But where's the fun in that?

Oh... and if you really want one less noodle flailing around your bars. use a short section of derailleur cable to pinch the comp adjuster in the position you want it on the Reba. You don't actually adjust compression damping or bother with lockout on a Hardtail. Do you? :/

These guys claim they can make a DM stem for 35mm bars at barely 100g...

So why not the Race Face DM35 one? Claimed weight is ~120g, the clamping surface seems decent, and it's made of 2014 aluminium. Not your 7075 of choice, but neither the cottage cheese 6061.

So why not the Race Face DM35 one? Claimed weight is ~120g, the clamping surface seems decent, and it's made of 2014 aluminium. Not your 7075 of choice, but neither the cottage cheese 6061.

Wrong length, no material specified, no width offset so clamp stance is narrow, and seen one day of testing.These guys claim they can make a DM stem for 35mm bars at barely 100g...

I think they have a real chance at winning the Tantrum graphic design competition though...

Take a look at their website and see what name they've come up with for their grips...Wrong length, no material specified, no width offset so clamp stance is narrow, and seen one day of testing.

I think they have a real chance at winning the Tantrum graphic design competition though...

http://www.candyray.com/

Last edited:

I machined my own stem a long time ago in undergrad. It was a PITA honestly. I wouldn't do it again. Mostly getting the bar bore smooth and correct in a manual mill is a real bitch.Buy a mill! Buy an 7075 aluminium block! Problem solved. Maybe text @kazlx ?

Monkey stems is what we need!

The candy stem looks mint. Still not sold on the slide-on design though.

Maybe I should use my SolidWorks license for something useful just once.

Easy enough to design however and easy to do in a CNC with a Z-axis surfacing cut for the bar bore.

At the moment I'm designing a Scott's steering damper sub-mount setup for Gemini/sasquatch that gives a custom reach for his dirt bike.

Take a look at their website and see what name they've come up with for their grips...

http://www.candyray.com/

"wife beaters?"

Sweet. I'd totally trust a 100g stem from those guys. The only stem I've ever seen truly broken (as in separated bar) is an enve stem, but I'd bet that's a good candidate just based on their website.

They're in poland, so @norbar needs to step up and explain

Did they also spell their own company name wrong on the bottom of their website? Fack..."wife beaters?"

Sweet. I'd totally trust a 100g stem from those guys. The only stem I've ever seen truly broken (as in separated bar) is an enve stem, but I'd bet that's a good candidate just based on their website.

They're in poland, so @norbar needs to step up and explain

greepsDid they also spell their own company name wrong on the bottom of their website? Fack...

My buddy has a Sunnen Hone at the shop. Would be easy to cut them like 1/2 thou small and hone them to size on a fixture.I machined my own stem a long time ago in undergrad. It was a PITA honestly. I wouldn't do it again. Mostly getting the bar bore smooth and correct in a manual mill is a real bitch.

Easy enough to design however and easy to do in a CNC with a Z-axis surfacing cut for the bar bore.

At the moment I'm designing a Scott's steering damper sub-mount setup for Gemini/sasquatch that gives a custom reach for his dirt bike.

Last edited:

I'll model/detail something next week if someone has requirements for something that isn't already on the market.If any of you cad monkies want to draw up something, I could probably work on getting them made.

I've run the same Ti bolts in my current stem for 8 years now.Just curious here, you're going to specify out ultra hard alloy and then run ti bolts in it?

My buddy @toodles has done the same for ~4 years if I recall correctly and he's a fair bit heavier than me, both our stem/bolt combos have been on ~4 DH bikes each and probably been to as many countries worth of chairlift parks. We've never broken any Ti bolts, and I'm on my 4th handlebar with it, think he's on his 3rd. Both on 800 wide bars atm.

I feel like Ti bolts aren't a problem. In fact I don't think 2014 alloy is a problem either, but my current stem is 7075 and I'd just like to keep that if possible - I'm definitely not saying everything outside my criteria is bad or anything - but I'm in no rush and would prefer something equal or better than what I currently have.

I try to buy the best parts I can and keep them for a *really* long time (another 8-year stem would be nice) so it's nice to spend the time to make the right choice - I had a similar thread about pedals here on RM and I'm still using the ones I picked there.

Last edited:

OT: which ones? Found no final conclusion.(...) I had a similar thread about pedals here on RM and I'm still using the ones I picked there.

Spank Spike with Ti spindles, also have Oozy/Ti on my trailbike (it's the same pedal just with more machining on the body). They've been pretty good.OT: which ones? Found no final conclusion.

Dude. you weigh fuck all don't you?

rider weight definitely has to be taken into consideration when recommending Ti.

No way I'd ever run a Ti pedal spindle. I bend chromo pedal spindles and (M800) Saint crank arms FFS! Ti (in my experience) shears far too easily.

rider weight definitely has to be taken into consideration when recommending Ti.

No way I'd ever run a Ti pedal spindle. I bend chromo pedal spindles and (M800) Saint crank arms FFS! Ti (in my experience) shears far too easily.

I can't believe I didn't think of the cable trick! I had the cartridge apart, seeing what I could do, since the POS defaults to lockout. Took all of five minutes to use a scrap cable and is a big improvement! Thanks!You don't actually adjust compression damping or bother with lockout on a Hardtail. Do you? :/

165-170# in American numbers.Dude. you weigh fuck all don't you?

rider weight definitely has to be taken into consideration when recommending Ti.

No way I'd ever run a Ti pedal spindle. I bend chromo pedal spindles and (M800) Saint crank arms FFS! Ti (in my experience) shears far too easily.

You do realise there's different qualities of Ti and different dimensions of Ti components - so if we're talking about things like Ti pedal spindles the design and support/loading plays a large part in its load capacity (i.e. Ti may be appropriate for some pedals and not for others). If you're buying $1 Ti bolts off ebay they're probably not going to be as strong as a certified bolt from a reputable source either.

For reference - I've bent far more chromo pedal spindles than Ti in total (if you think I don't wreck stuff you're sadly mistaken), and I think that's partially due to the fact that a lot of "chromo" spindles aren't as strong as they could/should be. You definitely can't generalise based on material without specifying alloy at least.

Some facts though:

- Most pedals don't use the strongest grades of steel available for spindles

- Cheap Ti spindles and bolts from no-name brands can suck (no surprises here)

- Most steel bolts in MTB parts are far from the strongest grade of steel (tensile strength in brackets), with stems often using 8.8 (830MPa) or 10.9 (1040MPa) grade bolts instead of the strongest 12.9 (1220MPa). A few stems I looked into with this thread used stainless bolts (~800MPa). Titanium can range from 950-1100MPa so in a lot of cases a quality Titanium upgrade will leave you with a stronger or equal strength bolt.

- Even if you weighed 200#, the ~8% leverage increase of my wider bars would put more loading on my stem bolts than yours.

- Literally not a single rider on the WC DH circuit I have seen is using cranks that are as heavy as the original M800, many who would be much larger and faster than both of us (and I do love and use Saint cranks) - so maybe at this point we need to differentiate between products being strong enough and you having a one-off failure / being a hack.

Last edited:

Hahaha, come on Gary, this is a thread about helping me pick a stem.

I'm not telling anyone to run anything, in fact I was asking people to tell me.

It's where I get to learn about a bunch of cool products and potentially put some shiny bling on my bike.

@Mo(n)arch - meant to ask earlier, what don't you like about the slide-on design, is it just the inconvenience or do you think there is a functional fault?

I'm not telling anyone to run anything, in fact I was asking people to tell me.

It's where I get to learn about a bunch of cool products and potentially put some shiny bling on my bike.

@Mo(n)arch - meant to ask earlier, what don't you like about the slide-on design, is it just the inconvenience or do you think there is a functional fault?

Actually it's more of a personal preference really. At some point I had two bars that differed solely in height on two different bikes and swapped them out to see how bar height affected my riding. It was awesome to just open the screws of the brakes and the stem and having the bar plus grips already in your hands.@Mo(n)arch - meant to ask earlier, what don't you like about the slide-on design, is it just the inconvenience or do you think there is a functional fault?

On the other side I'd fear to scratch my bars during the assembly or disassembly of the bar-stem combo, but that's maybe a no problem.

Another idea/question: Having dealt with tolerance problems in my old job in several occasions, how would a worst case scenario of 0,1 - 0,2mm of tolerances (paint, maybe an off product) affect the clamping and the forces in the stem with such a minimum of material around the bar? And that regarding in both scenarios: Overlap or play.

I reckon with painted parts milled in high production numbers the tolerances above aren't that far off, are they?

Last edited:

Fair call. I'm not too fussed as I rarely swap things out, and I think the single bolt clamp gives better load distribution. Valid point on the scratching thing though, potentially a concern during removal after it's been clamped for a while.Actually it's more of a personal preference really.

Another idea/question: Having dealt with tolerance problems in my old job in several occasions, how would a worst case scenario of 0,1 - 0,2mm of tolerances (paint, maybe an off product) affect the clamping and the forces in the stem with such a minimum of material around the bar?

I think every good stem (and bar if alloy) should be anodized - paint/powdercoat gives inferior tolerances like you said, is an inferior finish in terms of long-term aesthetics, and adds weight for no reason. To answer your question though - most painted parts with clamping surfaces are re-machined after painting though - eg frames, boxxer crowns, painted stems, inside of painted brake lever clamps etc. This way tolerances are kept intact - however it also leaves raw aluminium which has a lower surface hardness than anodized aluminium and is generally just a poor quality finish - if you want to be pedantic.

Plan for maximum material condition (MMC) on each part. Also, allow some amount of flex in the front plate or in the ring that surrounds the bar. The bar itself will also have a small degree of ovalizing to it when clamped. The machining/bar forming isn't 100% perfect, and your clamping won't be either (gap won't be 100% equal on both sides of the clamp).Actually it's more of a personal preference really. At some point I had two bars that differed solely in height on two different bikes and swapped them out to see how bar height affected my riding. It was awesome to just open the screws of the brakes and the stem and having the bar plus grips already in your hands.

On the other side I'd fear to scratch my bars during the assembly or disassembly of the bar-stem combo, but that's maybe a no problem.

Another idea/question: Having dealt with tolerance problems in my old job in several occasions, how would a worst case scenario of 0,1 - 0,2mm of tolerances (paint, maybe an off product) affect the clamping and the forces in the stem with such a minimum of material around the bar? And that regarding in both scenarios: Overlap or play.

I reckon with painted parts milled in high production numbers the tolerances above aren't that far off, are they?

Random update, wife bent two pairs of bars this weekend. Easton havoc and a race face, starting to wonder if the wider clamping location doesn't allow the bar to flex At all and just forces it to bend?

Both times her crowns were slightly twisted too, so not light impacts by any means but I've also crashed hard enough to to twist the crowns but never Brent bars.....just a thought?

Both times her crowns were slightly twisted too, so not light impacts by any means but I've also crashed hard enough to to twist the crowns but never Brent bars.....just a thought?

Random update, wife bent two pairs of bars this weekend. Easton havoc and a race face,

(Havoc stem + Atlas bars are on my bike, too) However, I wrecked quite hard on Friday and my bars did not bend.

I got 9 more hours to kill, might as well micro analyze things lol

(Havoc stem + Atlas bars are on my bike, too) However, I wrecked quite hard on Friday and my bars did not bend.

Sounds pretty crazy, clearly your wife is the real MVP.Both times her crowns were slightly twisted too, so not light impacts by any means but I've also crashed hard enough to to twist the crowns but never Brent bars.....just a thought?

It looks like the Havoc is about the widest you can get so maybe a contributor, but it's not that much wider than the others really so maybe just unlucky crashes.

I decided the ANVL was still the best of the bunch for me and emailed them a few questions before ordering, but no reply after 7 days. Re-sent this morning, will see how it goes.

-

This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.

By continuing to use this site, you are consenting to our use of cookies.